M-Tronix provides an innovative and flexible range of conveyor control, protection and monitoring products and systems. These cover multiple applications, across short and long conveyors, all controlled from one module, for up to single conveyor lengths of 50klms and more. Widely engaged around the world and proven to work in remote locations with difficult environmental demands.

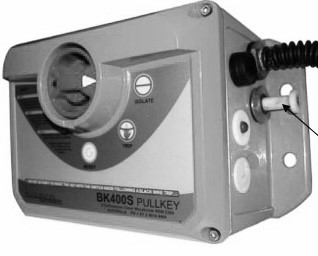

The BK400 Pullkey is a lanyard switch designed to provide pull wire protection on conveyors, it is available in two models.

These are the BK400S – single shafted key, which operates in a balanced pullwire configuration and the BK400D dual

shafted key, where the two pullwires operate mechanically independent of one another.

Flexible Design to Suit all Applications.

Temperature compensation is necessary where variations in temperature will cause the length of the pull wire to vary.

This we achieve by supplying a Tension Assembly to accept the extensions of the wire and the distribution back into the

system when movement occurs.

M-Tronix Bramco is proud to announce the recent

completion of our CCMS Signal Line Conveyor

Control and Manage- ment System on several

overland conveyors in central Queensland. The CCMS signal line was selected as a safety monitoring system for these conveyors which ranged in length from 1.5km (4950 feet) to 21km (69,300 feet).

We have to-date supplied over 300 systems worldwide and to countries such as

Australia, Sth Africa, Zambia, USA, Brazil, Peru, Ukraine, Belarus and others.

The M-Tronix Bramco Conveyor Control System is both powerful and flexible with

the latest in self diagnostics. All faults along the system are displayed on the control

screen. Our Conveyor Control system embodies the requirements of Occupational

Health and Safety Acts, duty of care and is operationally Totally Fail Safe.